Back

Back

SAMPLE PREPARATION - METALLOGRAPHIC

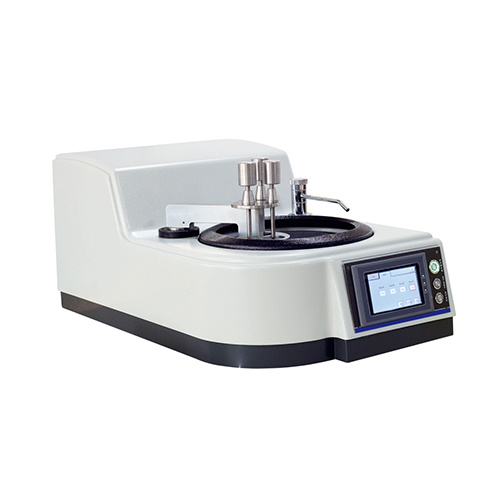

LAP-100X

PRODUCT ADVANTAGES

- Simultaneously place three samples and swing them left and right to achieve semi-automatic grinding and polishing;

- The downward pressure of a single sample can be customized and adjusted

- All grinding and polishing parameters, such as speed, grinding and polishing time, rotation direction, and water valve closure, are automatically saved and easily accessible;

- Four speed manual mode, eight sets of automatic mode;

- The parameters for each mode are set by the user; Each step of grinding and polishing can be set with stepless speed regulation;

- The position of the water droplet can be rotated and adjusted, the water flow rate can be adjusted, and the grinding and polishing process can start and end, as well as the water can be automatically turned on and off;

Model | LAP-100X

Sample oscillation frequency | 9 times/minute

Single sample downforce pressure | 300 grams (customizable and adjustable)

Motor power | 1Kw

Water valve opens automatically | Yes

Working disk diameter (mm) | Φ 254 (optional Φ 203/Φ 230, can be customized with Φ 304)

Speed (r/min) | 5-1500

Direction of rotation | Counterclockwise/clockwise optional, forward or reverse automatic switching

Four speed manual(r/min) | V1=200, V2=400, V3=600, V4=800 (user can customize the speed)

Automatic grinding parametersParameters include: speed, time and direction of rotation of the mill | 64 kinds

Grinding parameter | User can set and call

Common material sample preparation process | Steel, iron and other 12 kinds of material sample preparation process, each material up to 10 steps

Power source | Voltage: AC220V, frequency: 50HZ

Overall dimensions (mm) | 760 x 430 x 360 (L * W * H)

Weight | 30kg