Back

Back

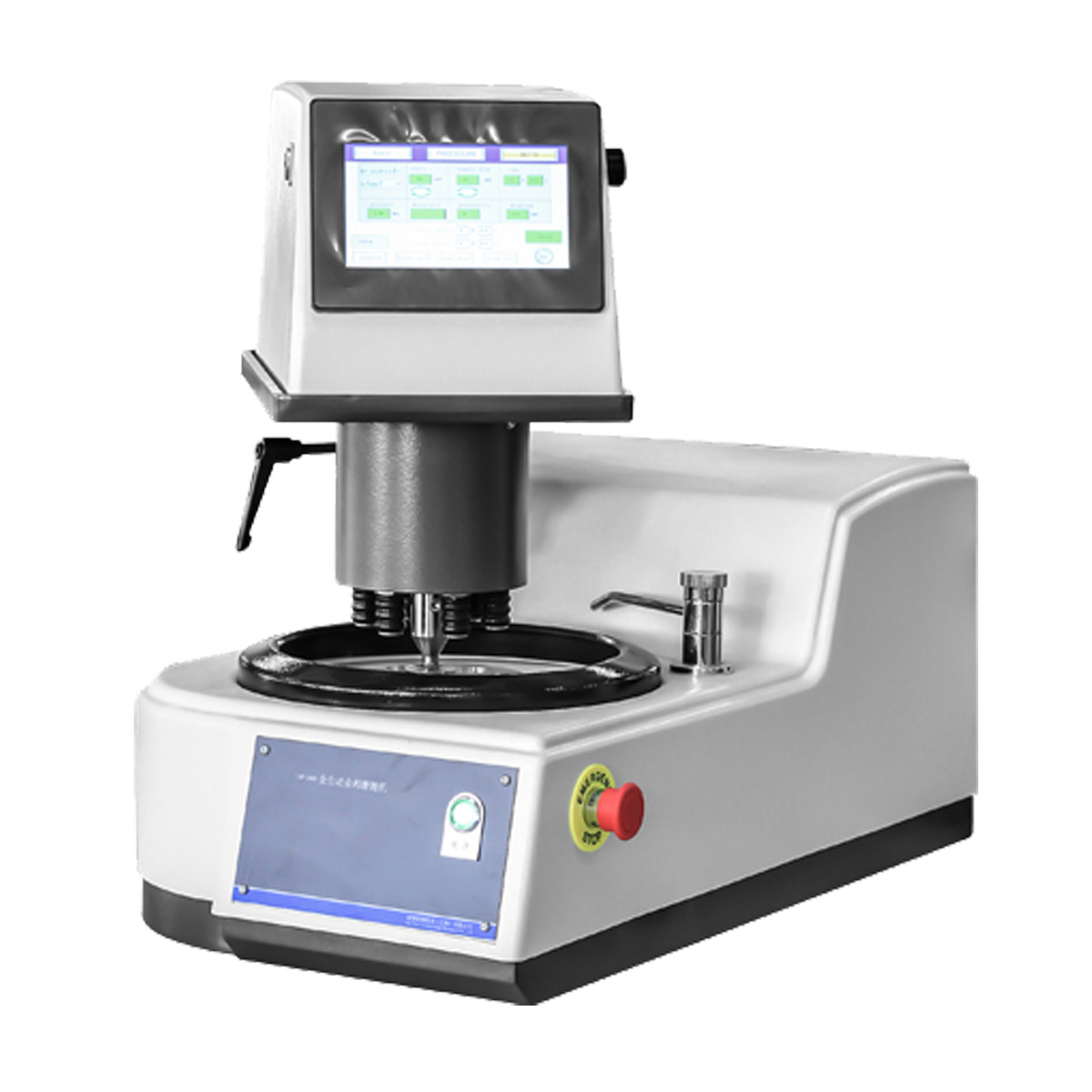

SAMPLE PREPARATION - METALLOGRAPHIC

LAP-1000/2000

PRODUCT ADVANTAGES

1. Single/double grinding and polishing disc: single sample is loaded independently.

2. PLC independently controls the grinding and polishing disc and sample disc: all grinding and polishing parameters such as speed, grinding and polishing time, rotation direction, water valve closing, etc., and automatically saves and is easy to call.

3. Touch screen interface: grinding and polishing parameters are easy to set, status display is intuitive, and operation is simple.

4. The grinding and polishing disc and sample disc rotate with stepless speed change, and the rotation direction can be switched.

5. PLC controls the on and off of water and abrasive drippers.

6. Working mode:

6.1 Fully automatic mode:

According to the sample material or the user's habits, 30 sets of processes (processes) can be set and called, each set of processes can contain 10 process parameters (each process has process parameters for a certain grinding or polishing process: grinding disc and grinding head rotation speed, grinding and polishing time...)

6.2 Single process mode:

According to each step of the grinding and polishing process, 30 process parameters can be set and called: grinding disc and grinding head rotation speed, grinding and polishing time, water on and off...

6.3 Manual mode:

Operate a certain function of the equipment separately

7. Easily replace the magnetic anti-sticking disc to complete all processes such as rough and fine grinding and rough and fine polishing of various samples. One disc is equivalent to N discs.

8. Electromagnetic automatic brake replaces the manual grinding head locking wrench, which is more convenient.

9. The U disk stores 300 processes, which can be imported and exported.

10. Chinese/English interface switch

11. High precision, stable operation, low noise.

12. Optional dropper.

13. Optional mobile terminal remote control operation module.